– Production of the iconic Bentley W12 engine will end in April 2024 after more than 100,000 units have been produced in Crewe.

– Bentley’s strategic decision to become a leader in sustainable luxury mobility.

– The milestone is marked by the confirmation of the best performing version.

– The performance of the sold Bentley Batur is confirmed as 750 hp. with 1,000 Nm of torque when the test engine completes its endurance test.

– Aim to retrain and get in business all 30 fellow W12 productions.

-The-W12 engine line will be an expanded range for V8 and V6 hybrid engines.

– There are very few slots left for W12 orders.

(Crewe, February 22, 2023) Bentley today announces the end of production of its 12-cylinder petrol engine in April 2024, with over 100,000 examples of the iconic W12 being handcrafted at the Dream Factory in Crewe, England.

The decision was made as Bentley’s acceleration is holding back sustainability through its Beyond100 strategy, which envisages the company’s entire product range being fully electrified by early next decade, bringing the fleet’s average CO2 emissions to 0 g/km CO2 become. This journey has already begun with the launch of the Bentayga and Flying Spur hybrid models, for which demand has exceeded the company’s expectations. When production of the W12 ends next year, the entire Bentley range will be available with a hybrid drive option. In the meantime, the Continental GT engine, which was first introduced in the series and has powered Bentley for the last 20 years, will be history.

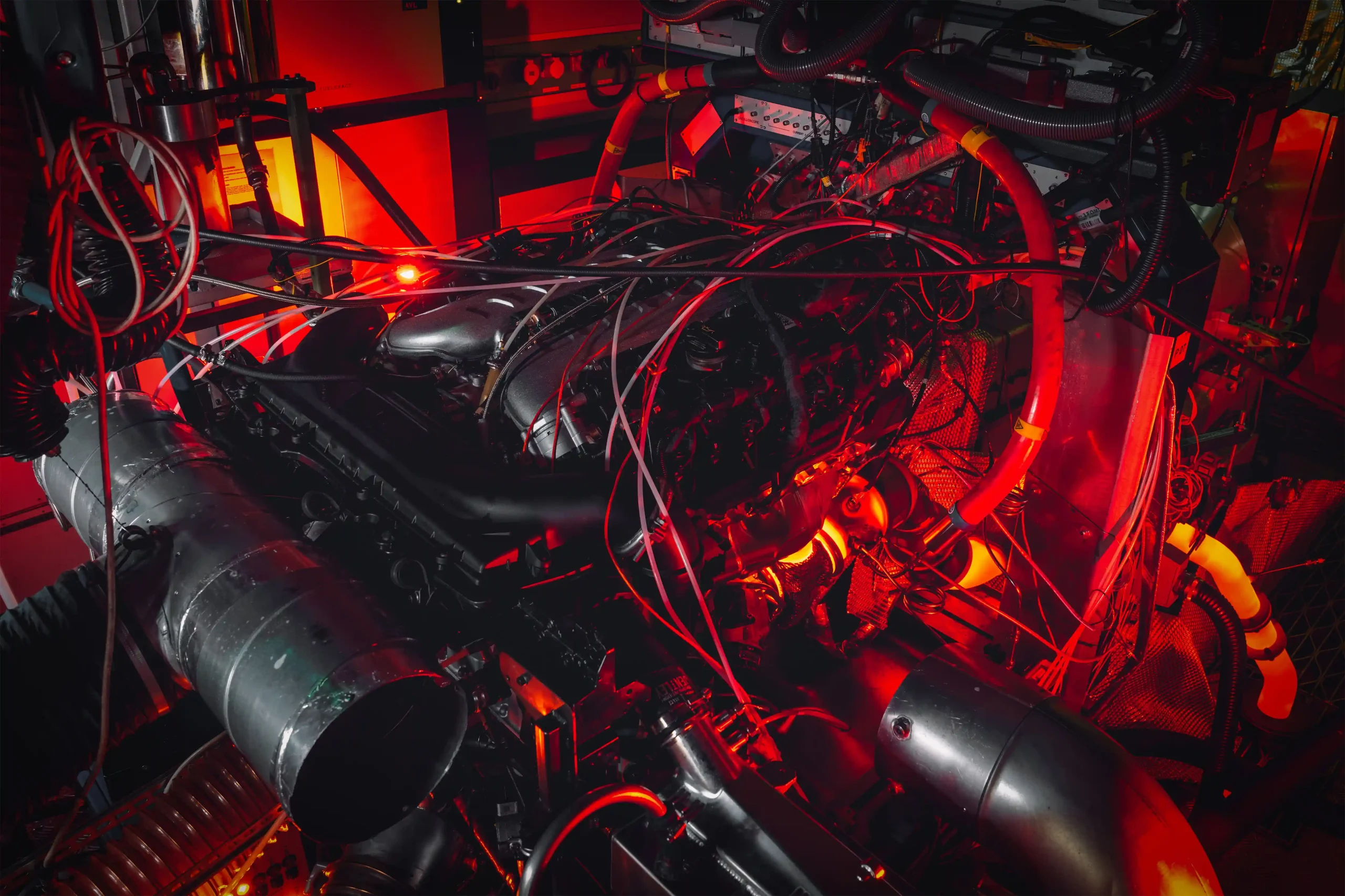

Bentley won’t let the W12 go without a dramatic farewell. We recently completed development of the most powerful version of W12 ever made. The final version of this powerful engine, designed for hand-built installation in just 18 Bentley Baturs, has now been confirmed at 750hp. and 1000 Nm of torque. The increased torque produces the typical Bentley ‘crust plateau’, operating from 1750 to 5000 rpm, with peak power at 5500 rpm.

Bentley’s Chairman and Chief Executive, Adrian Hallmark, comments:

“Our progressive journey towards sustainable luxury mobility means making changes to every area of Bentley Motors. When we first launched the W12 back in 2003, we knew we had a mighty engine that would propel both our cars and the brand forwards at speed. 20 years and more than 100,000 W12s la ter, the time has come to retire this now-iconic powertrain as we take strides towards electrification – but not without giving it the best send-off possible, with the most powerful version of che engine ever created.

“The 750 PS titan that Mulliner has created for the Batur marks che end of a development journey of which our engineering and manufacturing colleagues should be extremely proud, and when production finishes in April next year we aim to retrain and redeploy all of the skilled craftspeople who still build each engine by hand.”

After an exceptionally grueling series of endurance tests, the supercharged engine has proven to be more reliable than ever and as such will power Bentley’s most powerful road car ever. Although all Batur vehicles have been sold, limited quantities of the 659hp version of the W12 engine offered in the Speed versions of the Continental GT, Bentayga and Flying Spur and the Continental GT Mulliner and Flying Spur Mulliner can still be offered are ordered. Demand for these latest W12 powered Speed and Mulliner models is expected to be strong and buyers looking to purchase one of the latest 12 cylinder Bentleys should contact their dealer at the same price.

Bentley’s goal is to retrain and redeploy all 30 skilled technicians who manually assemble and test each W12 engine at Bentley’s carbon neutral Crewe plant. In the meantime, the W12 engine plant will give way to an expanded assembly line for other Bentley engines used in plug-in hybrid models.

Since the primary creation of the 6.0-litre, twin-turbocharged W12 in 2003, the engineering crew in Crewe has usually advanced the overall performance of the engine in phrases of electricity, corque, emissions and refinement. Over the ultimate 20 years, electricity has accelerated with the aid of using 37 consistent with cent and corque with the aid of using fifty four consistent with cent, even as emissions were decreased with the aid of using 25 consistent with cent. lnitially this become thru evolution and optimisation of che manipulate systems, upgrades in che oil and cooling designs, turbocharging generation and greater powerful injection and combustion processes. For the release of the Bentayga in 2015, the W12 become absolutely redesigned from the sump up, and it is that model of the engine that stays in manufacturing today – offering cylinder deactivation, direct and port injection, and twin-scroll turbos.

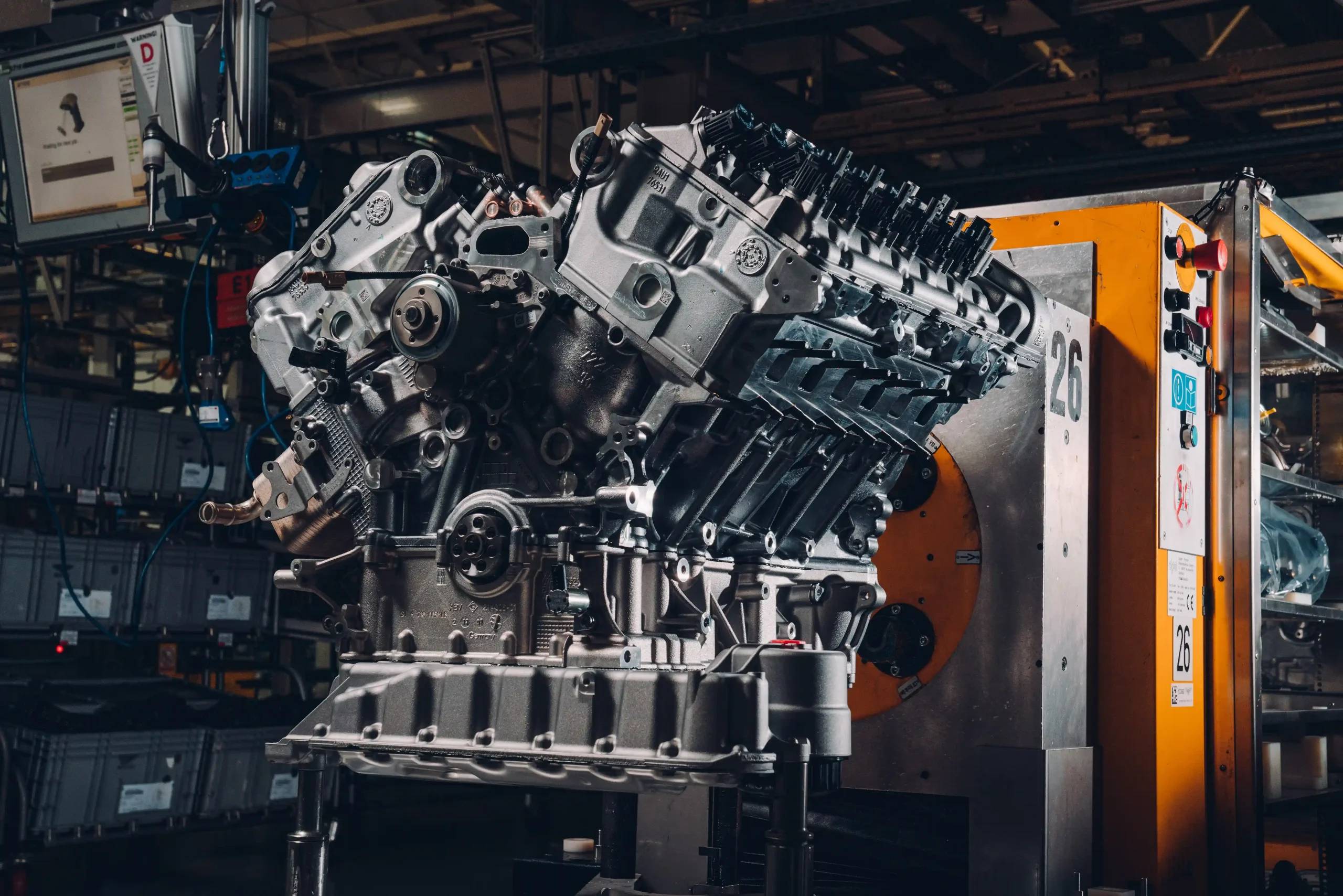

Handcrafted by a team of craftsmen over a period of 6.5 hours, each W12 engine is then put through a rigorous testing program lasting over an hour on three specialized diagnostic machines. Each week, an engine undergoes an extended test cycle and is then completely disassembled for inspection.

The W12 engine plant will deliver more than 105,000 engines this year before it turns 20 years old.

Batur Showcases the Ultimate W12

For the latest and definitive version of the W12, the Mulliner engineering team have redesigned the intake, exhaust and cooling systems to unleash more power and torque than ever before. Under the watchful eye of Mulliner CTO Paul Williams (who previously led development of the second generation W12), the engine now produces 750bhp.

The turbocharger compressors have been redesigned to increase efficiency and the ducts that supply them with air have been enlarged by 33% – at peak power the new engine uses over a tonne of air (1050kg) per hour. Larger aftercoolers with 10mm more depth and new core geometry remove 35% more heat from the compressed intake air, lowering intake temperatures more, which means a tighter charge for more power.

The new intake and turbo system is combined with a heavily revised engine calibration to free up additional available crankcase, and then the complete engine system is combined with a new gearbox calibration to take advantage of the extra power and crankcase for a better driving experience.

The Evolution of an lcon

Bentley’s legendary 6.0-litre twin-turbo W12 engine from 2002 has evolved into the latest version of the W12 engine used in today’s range. The unique W configuration means the engine is 24% shorter than the equivalent V12, giving it an advantage in layout and maximizing usable cabin space.

The latest generation of the W12 was presented in 2015 at the Bentayga. The heavily revised engine has a crankcase that is 30% stronger than its predecessor and coated cylinder surfaces to reduce friction and improve corrosion resistance. The low-alloy steel coating is applied to the holes using the Atmospheric Plasma Spray (APS) process.

The cooling system has also been improved: the engine has three separate coolant circuits. The first is to warm up the cylinder heads to the optimum operating temperature for best engine performance and low emissions as quickly as possible. The second cools the engine block and oil system, while the third is responsible for the thermal load on the turbochargers. Each system has its own water pump to optimize individual control.

The W12 combines high-pressure direct injection (200 bar injection pressure) with low-pressure port injection (six bar). The combination of these two systems ensures maximum driving comfort, reduces particulate emissions and optimizes engine performance and performance.

Twin scroll turbochargers minimize turbocharger response time and provide a more efficient exhaust system. The exhaust pipes for the three front and three rear cylinders are separate and feed the twin-branch impellers. The turbocharger housing is welded directly to the exhaust manifold and has built-in speed sensors to allow the engine to control the operation of the turbocharger for maximum efficiency.

The Bentley Variable Displacement System disables half of the engine under certain conditions. The intake and exhaust valves, fuel injection and ignition are mapped to specific cylinders, allowing the engine to run like a six-cylinder for greater efficiency. The system operates in gears three through eight in this mode, under 3,000rpm and up to 300Nm of torque, and has built-in speed sensors that allow the engine to manage the turbo for maximum efficiency.